PVL INTERNATIONAL

COMPARISON WITH THERMIC CUTTING

The PVL Cutting torches are delivered in a Special case including our unique in water igniting device. It’s also a part of our fast, economic and easy to use system.

Below you can have a look at the comparison with thermic cutting a company made between our torch and a thermic variant.

If you are interested in the PVL Cutting Torch, you can request a quotation or contact us if you have a question.

COMPARISON WITH THERMAL CUTTING

PVL CUTTING TORCH

REQUIRED MATERIAL

- PVL Torch

- Hoses 100 meter

- Gas regulator

- Oxygen O2 per m³

- Gas mixture per 79ltr

- Underwater igniter

TRANSPORTATION WEIGHT AND DIMENSIONS

Torch, hoses, regulator & spares

L x B x H = 58 x 78 x 40

Total Weight = 65kg

MAP Gas bottle

L x B x H = 30 x 30 x 127

Bottle weight = 32kg

Gas weight = 34kg

CONSUMPTION PROPORTION

1 Bottle of Gas to 10 bottles of Oxygen

OXY THERMIC CUTTING TORCH

REQUIRED MATERIAL

- Oxy/Thermic torch

- Hoses & 50mm cable 100 meter

- Earth cable 100 meter

- Welding generator

- Oxygen O2 per m³

- Electrodes per box

- Gas regulator

- Cut off switch (Knife switch)

TRANSPORTATION WEIGHT AND DIMENSIONS

Torch, cables, switch, regulator & spares

L x B x H = 120 x 100 x 75

Total Weight = 300kg

Thermic electrodes per box

L x B x H = 50 x 10 x 10

Total Weight = 12kg

DC generator (Powcon)

L x B x H = 84 x 51 x 50

Total Weight =100kg

CONSUMPTION PROPORTION

10 Packs of Electrodes to 10 bottles of Oxygen

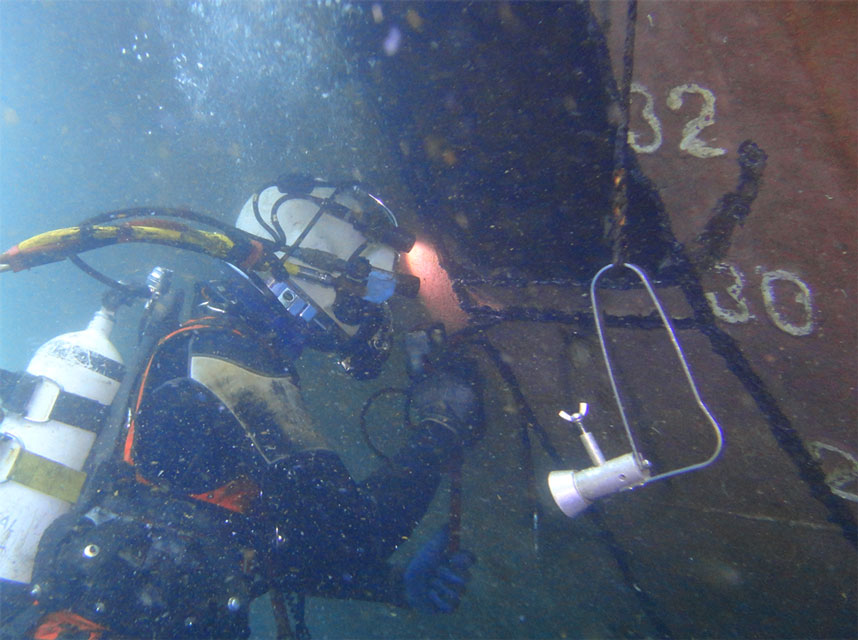

PVL CUTTING TORCH TEST

Diver

Location

Material

Initial Oxygen Pressure

Final Oxygen Pressure

Cylinder Capacity

Total O2 Consumption

Itr Initial Gas Pressure

Final Gas Pressure

Consumed electrodes

Time Began

Time Finished

Total Time

Cutting distance

PVL CUTTING TORCH

Diver 1

Weert

Steel strip 160x1200x25mm

180 bar 120 bar

160 bar 100 bar

40 ltr. 47 ltr. 50 ltr.

1740 ltr.

-

-

Not applic

11:56 uur

12:02 uur

6 min

154 cm

OXY/THERMIC CUTTING TORCH

Diver 1

Weert

Steel strip 160x1200x25mm

195 bar

50 bar

50 ltr.

7250 ltr.

Not applic

Not applic

4

12:27 uur

12:33 uur

6 min

48 cm

CONCLUSION OF THE PVL CUTTING TORCH

ADVANTAGES

- Lightweight & compact for transport

- Low consumable costs

- Easy to ignite

- Simple operatioN

- Quick cutting in the right conditions

- Good vision of the cut through the material

- No risk from temporary blindness (arceye)

- No power supply required (electricity)

- Equipment does not need to be rust-proof

- Clean, straight cut

- Minimal maintenance & spares

- No excuses relating to torch problems

- Less chance of leaving uncut material (bridges)

- Ability to cut thick material

DISADVANTAGES

- Experience and practice is needed to cut some

types of bracings - Nearly everything is possible to cut

- Louder than the Oxy/Thermic torch

- Gas should not be too cold

- Gas bottles should be kept in a warm environment